Switching from LED to laser won't be overnight. On the contrary, in the foreseeable future, LED based lamps will still be the main means of generating white light. However, solid state lighting systems based on laser diodes have been used in high brightness lighting applications, and several manufacturers have now produced them.

The power of laser diode pumped luminaires is to avoid the decrease of LED efficiency. But that's not the only advantage. In addition to Soraa and several others, the chips used by other manufacturers of LED sources do not contain wavelengths shorter than about 450nm. Therefore, when the cheap LED with the peak wavelength of 450-460nm is used to pump the phosphor, the light source will be insufficient in the purple part of the spectrum.

White light can be avoided by using a 405nm ultraviolet light emitting diode laser. These devices are cheap, efficient, and also available in the market. Using short wavelength phosphor pumping, the spectral output is more abundant, the spectral coverage is greater, and the color rendering index is higher than the typical LED pumping Bai Guangyuan (see Figure 1).

Figure 1

The chromaticity of light from laser diode pumped white light lamp is almost neutral (x=0.3305, y=0.3309), which proves the spectral richness of light source. The black line in the graph is the Planck trajectoryIn many cases, the quantity is more important than the quality of white light. In this way, laser diode pumped light is very strong, so they are ideal high intensity light sources for building lighting, searchlight and car headlights. Another property of the laser source is that the emitted light beam has minimal divergence, almost parallel.

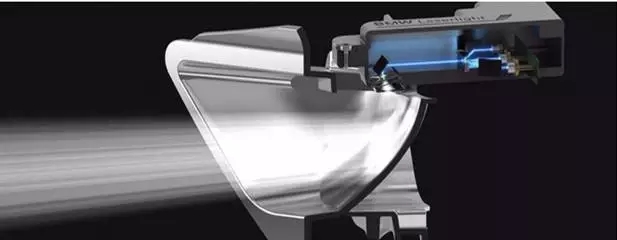

The advantages of laser pumped light sources have attracted the attention of automakers, and they are actively installing laser headlights for high-end models. Like the penetration of LED lighting in the automotive industry, high-end models are leading the way, including some of BMW's models (see Figure 2).

Figure 2

BMW's laser headlamp has a single laser diode, beam combiner, phosphor target and reflector assembly.Your laser pumping structure

Unlike LED, different arrangements are required when pumping the phosphor using a laser diode. Because of the directional characteristics of laser radiation and its high strength, it is impossible to simply deposit phosphor on the top of the pump device. On the contrary, more optical arrangements are needed, such as combinations of phosphor plates and reflectors, or phosphor coated spheres (see Fig. 3).

For these two methods, one or more than two diodes can be pumped as long as the appropriate technique is used to combine multiple laser beams. This means that there is no upper limit for the optical power of the laser pump module. Another advantage of using the remote pumping structure is that the phosphor is not on the hot part, which prevents the phosphor from heating during operation and greatly prolongs its service life.

A relatively simple method of laser pumping is to guide the laser to the phosphor plate and to collimated the radiation obtained with the reflector (see Fig. 3 (a)). However, in optical power conversion, phosphor coated integrating spheres are more effective (see Figure 3 (b)).

Figure 3 typical optical settings for laser diode pumping

According to the need for low power or high power light source, you can use other programs. For example, a small luminaire can pump the entire phosphor plate with a beam expansion lens. This method, as shown in Figure 4, describes the ray tracing simulation of a single pass light.

Figure 4

An efficient pumping device for miniature laser pumping lamps. The pump light (red beam) enters from the left side and extends through the concave beam expansion lens to the phosphor coated glass plate on the right and is incident to the organic silicon bound phosphor layer. The down conversion light shows blue light. In the diagram, the fluorescent plate is opaque and separated from the green reflector, so that the light path in the reflector shell can be seen. In the actual lamp, the fluorescent plate (the transparent glass sheet allowing the light to escape out) is sealed to the reflector. Only a small amount of light is reflected back to the left side of the laser module (not shown).Although laser pumped white light sources have many advantages, their limitations must be taken into account. Like a LED based light, the emitted light consists of two different components: the down conversion light from the phosphor, and the remaining unconverted laser. However, the use of laser, the biggest difference is that internal consistency, which can lead to spots that appear in the visible light and dark spots on the surface.

Speckle can not be ignored, in addition to distracting people, it also has a negative impact on visual perception, it will hinder the detection of lighting objects spatial detail. Tests show that spots reduce visual acuity by 40%, and reduce the ability to sense the spatial frequencies of the high and low levels. These problems are part of the reason why laser lighting is not popular.

Please note that using laser projectors to reduce the coherence of the laser by some means can transform the spots into acceptable levels. But with laser irradiation, the spots can even drop to a lower level. In this case, the spots are so small that they can be completely ignored. This is mainly because the good light design ensures that most lasers are converted to longer wavelengths without spots.

Another advantage is that the remaining laser shows very small spots, which is due to the fact that when it passes through the phosphor layer, it undergoes multiple scattering, and its coherence decreases. The phosphor pumped laser system has strong light, rich colors and no spots, which is better than the light produced by LED lamps.

Your support and opposition

The biggest disadvantage of laser pumped white light source is related to diode. First of all, the price of this chip is much higher than LED. Although widely used in data storage applications, laser diodes are much more expensive than LED for equivalent levels of light emitting diodes. Because of the high cost, the laser pumping phosphor system is expensive and can only be deployed in specialized, less cost conscious lighting applications.

One advantage of the laser pumped lighting system is that it can cover a wide range of output power. The power rating of commercial laser diodes ranges from a few watts to several watts, and a more powerful source can be formed by combining several laser outputs. However, this is not conducive to the life of the system. This is because diode lifetimes are less than LED lifetimes, especially when they operate at high driving currents.

Why diode life is low? This can be traced back to tiny, pre-existing crystal dislocations in the laser structure. These defects can be greatly increased when the device is powered by a high power level. The operation in this way will gradually form a dislocation network widely, known as dark line defects. They act as nonradiative recombination sites that reduce the light output of the device. The brightness of the diode decreases as time goes on, and the brightness of the pump is too low until the light output is lowered.

Encouragingly, with the increase in the maturity of the laser diode, this problem has not been so serious, but still needs to be further resolved. Switching to native GaN substrates that favor epitaxial growth may be a way to reduce the number of dislocations through the interface and increase the lifetime of the laser diode.

Another breakthrough of white light lighting based on lasers is the reduction of high cost through economies of scale. This will open up new markets for UV and near UV laser diodes. Although LED lighting is undoubtedly in the lead today, but in the next few years, please pay attention to the laser system.